Precision Aerospace Manufacturing

Delivering high-quality aerospace and defense components with uncompromising precision and reliability.

Our Services

Airmetal specializes in providing high-precision CNC machining services for the aerospace and defense industries.

Precision Manufacturing

State-of-the-art precision manufacturing for aerospace components with tight tolerances.

Quality Control

ISO 9001:2015 Registered and AS9100D Compliant quality control processes to ensure components meet highest industry standards.

Short-Run, Low-Volume Stamping

Cost-effective stamping solutions for low-volume production runs with quick turnaround times and minimal tooling costs.

Custom Solutions

Tailored manufacturing solutions for your specific aerospace and defense requirements.

Materials Expertise

Specialized knowledge in machining aerospace-grade materials including titanium, Inconel, and aluminum alloys.

Complex Geometries

Capability to machine complex parts with intricate geometries and challenging specifications.

About Airmetal

Precision CNC machining and machine fabrication in South Central Michigan

Airmetal Corporation is a precision CNC machining operation and machine fabricator, conveniently located in South Central Michigan.

We specialize in machined parts primarily for Aerospace and Military markets, along with special machines and machine modifications. Our focus is on short run, low volume processes that require precision and attention to detail.

Our capabilities extend to creating custom tooling, jigs, fixtures, and small dies with exceptional precision and quality.

Our Specialties

- ✓Machined parts for Aerospace and Military markets

- ✓Special machines and machine modifications

- ✓Tooling, jigs and fixtures

- ✓Stamping and fabrication

- ✓Small dies

Our Process

Our comprehensive process ensures high-quality manufacturing for every project.

Requirements Gathering

We start with collecting required information to understand your specifications.

Manufacturing & Quality Inspection

Using our advanced CNC machines, we precisely manufacture your components to exact specifications.

Finishing & Treatment

We apply any necessary surface treatments and finishes to meet your exact requirements.

Delivery

Your completed components are carefully packaged and delivered on schedule.

Why Choose Our Process?

We bring 75+ years of experience, precision and consistent quality across all components.

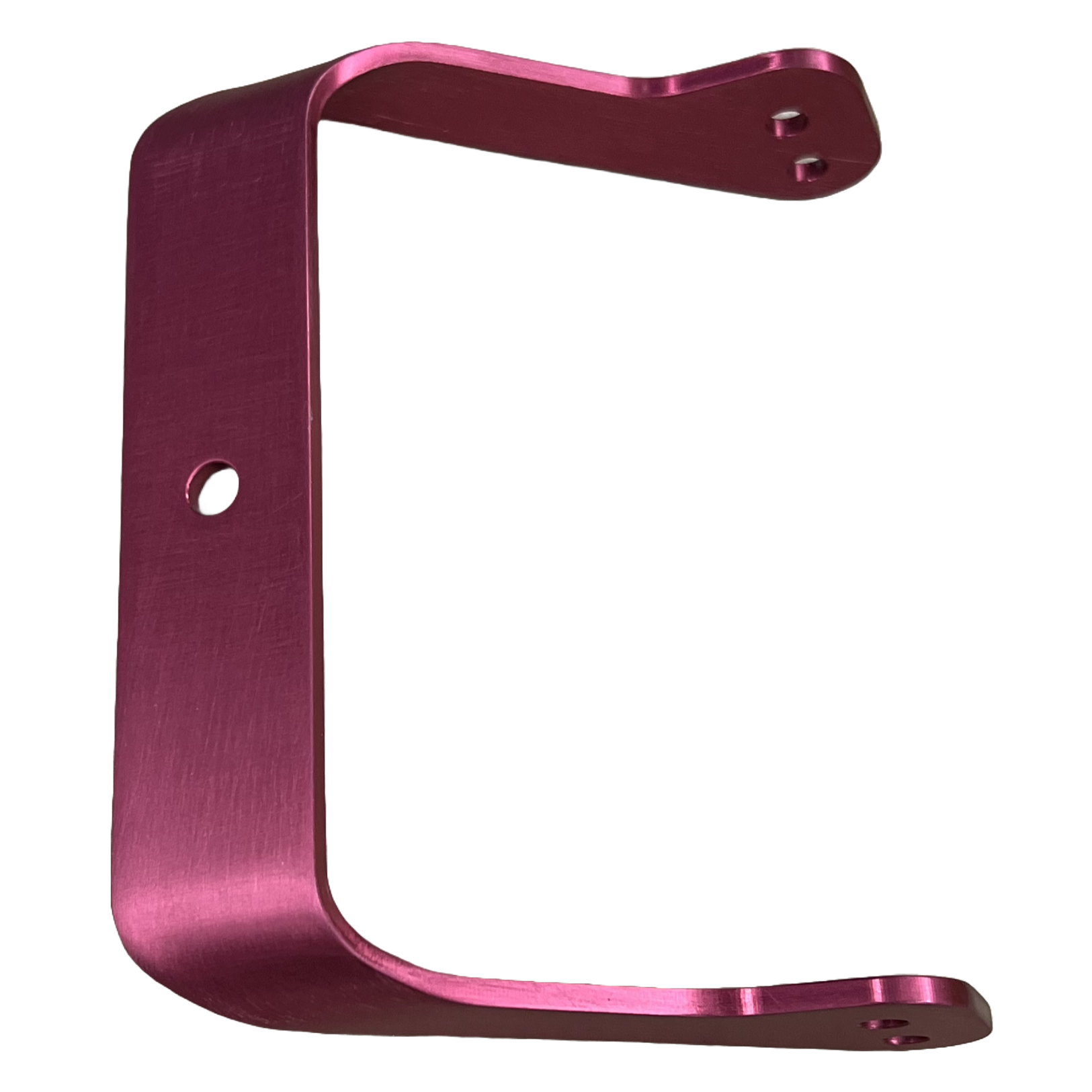

Product Gallery

We've done 1000's of parts, but here is a small selection of some of our favorites.

Frequently Asked Questions

Find answers to common questions about our aerospace and defense manufacturing capabilities

We have extensive experience working with a wide range of aerospace-grade materials, including various aluminum alloys (2024, 6061, 7075), titanium alloys, Inconel, stainless steel, and other specialty materials. Our team is trained to handle the unique machining requirements of each material.

Airmetal maintains industry-standard certifications relevant to aerospace and defense manufacturing, including being ISO 9001:2015 Registered and AS9100D Compliant. Our quality management system ensures consistent adherence to the strict requirements of aerospace and defense applications.

Lead times vary based on project complexity, material requirements, and current workload. For standard components, we typically deliver within 2-4 weeks. For complex or large-volume orders, lead times may increase, however we always provide accurate timeline estimates during the quoting process.

Yes, we offer comprehensive prototyping services for aerospace and defense applications. Our experienced team can help refine your designs, select optimal materials, and manufacture high-quality prototypes that accurately represent or can replace production components.

Our state-of-the-art CNC machines and skilled operators can consistently achieve the necessary tolerances for each project or component. We regularly work with the precise tolerances required for critical aerospace components.

Yes, Airmetal is fully compliant with International Traffic in Arms Regulations (ITAR) and can handle projects with various security classifications. Our facility and processes are designed to maintain the confidentiality and security required for defense-related projects.

Yes, we have the capacity and expertise to handle both small and large orders. Our experienced team ensure that we meet your specifications and deadlines efficiently. Contact us to discuss your project, and we’ll be happy to provide more details.

Don't see your question here?

Contact UsContact Us

Have questions or ready to start your project? Reach out to us today.